The two principal types of compressors currently being used in gas turbine aircraft engines are centrifugal flow and axial flow.

Much use has been made of the terms “centrifugal flow” and “axial flow” to describe the complete engine. However, the terms are applicable only to the flow of air through the compressor.

In the centrifugal-flow engine, the compressor achieves its purpose by picking up the entering air and accelerating it outwardly by centrifugal action. A single stage delivers a pressure ratio of around 5:1 & and a two stage around 8:1. Design of the more modern centrifugal compressors sees them approaching pressure ratios of 15:1.

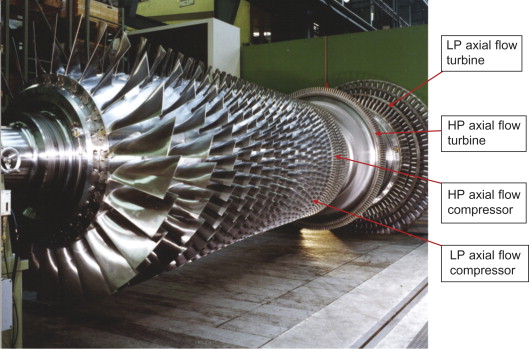

In the axial-flow engine, the air is compressed while continuing in its original direction of flow, thus avoiding the energy loss caused by turns. From inlet to exit the air flows along an axial path and is compressed at a ratio of approximately 1.25:1 per stage.

The centrifugal-flow compressor’s advantages are

(1) High pressure rise per stage

(2) Good efficiencies over wide rotational speed range

(3) Simplicity of manufacture, thus low cost

(4) Low weight

(5) Low starting power requirements

The centrifugal flow compressor’s disadvantages are

(1) Large frontal area for given airflow

(2) More than two stages are not practical because of losses in turns between stages

The axial- The axial-flow compressor’s advantages are

(1) High peak efficiencies

(2) Small frontal area for given airflow

(3) Straight-through flow, allowing high ram efficiency

(4) Increased pressure rise by increasing number of stages with negligible losses The axial

The axial-flow compressor’s disadvantages are

(1) Good efficiencies over only narrow rotational speed range

(2) Difficulty of manufacture and high cost

(3) Relatively high weight

(4) High starting power requirements (this has been partially overcome by multi-spool compressors)

From an analysis of the centrifugal and axial flow engine compressors at their present stage of development, the axial-flow type has definite advantages. Also, the advent of the split-spool axial compressor has made these advantages even more positive by offering greater starting flexibility and improved high-altitude performance.