Efficient maintenance operations require qualified, experienced and competent aircraft mechanics. However, airlines and MROs are about to face a new challenge: the existing workforce is diminishing but demand for mechanics is expected to rise sharply in the future.

This shortage risk is based on a retiring population and the effects of the pandemic, but may also be due to a lack of enthusiasm for a job which often offers little in the form of a clear career path.

Training is the starting point for new mechanics. However, it also needs to become an integral part of their on-going personal and technical development, to motivate them to secure efficient operations and personnel resources as well as to meet regulation requirements. Learning about aircraft structures, as well as the latest technologies, methods, tools and best practices: these are all part of this development.

Meanwhile, organisations in charge of training or employing mechanics – such as training centres, MROs and airlines – may be asking themselves if they should make or buy training, make or buy the training material and if training is an essential investment or just an inevitable cost.

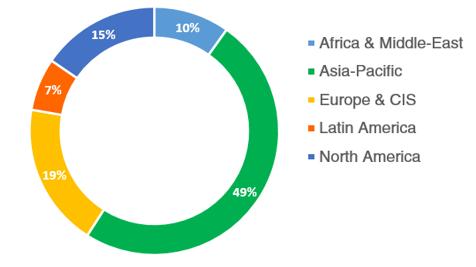

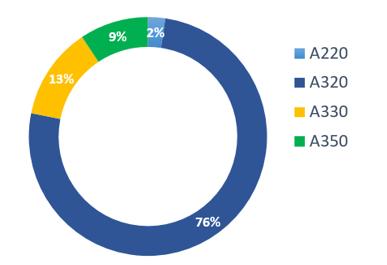

Forecasting future demand

Before the Covid-19 crisis, the cumulative, forecasted need* was for over 700,000 new aircraft maintenance technicians and engineers by 2035. It was already a challenge to:

- ensure a pool of mechanics;

- attract a new generation to a profession that requires initial, high personal investment and yet is undervalued;

- secure the right competences to maintain both legacy and the latest generation aircraft;

- keep this precious workforce and ensure that competences are maintained over time.

*Airbus Global Services Forecast (GSF)

An immediate effect of the crisis has been the retirement of a large senior population. On the one hand, this has helped many operators and maintenance repair organisations to adapt their workforce to the reduction in activity. On the other hand, it has increased the risk of a serious shortage of qualified mechanics in the future. Today, on the brink of market recovery, the overall cumulative need for new maintenance technicians and engineers in the longer term remains high. New mechanics will be required to compensate for the attrition of those who have left and to support the expected ramp-up of the worldwide fleet.

Need for new Airbus maintenance technicians and engineers over the next 20 years

Make or buy – the training investment

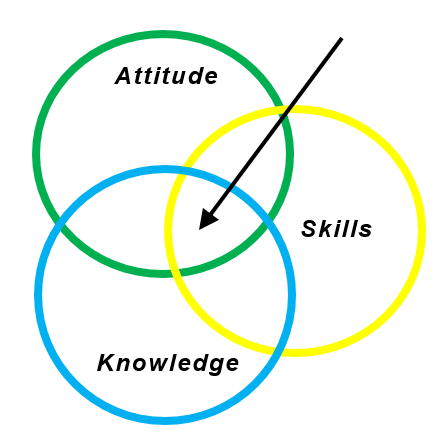

The priority for operators and MROs remains to secure safe and cost-efficient maintenance operations, while ensuring optimised aircraft availability. To achieve this objective, maintenance organisations need competent and qualified mechanics. Competence is of course acquired in the field but can take time to develop. This is where training serves to accelerate acquisition of the necessary competences, based on the KSA (Knowledge, Skills, Attitude) learning model, and to complete on-the-job experience.

Focusing on the target area

In addition, in the very regulated aeronautical environment, most maintenance training needs to comply with national aviation authorities for the management of competences. Training is too often perceived as simply a cost and not always performed whenever and wherever relevant. This means that, especially when under financial pressure, organisations may be tempted to focus only on the cost of the training solution and/or develop their own ones to compensate. 3 questions for operators and maintenance organisations to ask themselves:

- Is it relevant and efficient for operators or MROs to set up and maintain training organisations when they have their own priorities: transporting passengers and freight and/or maintaining the aircraft in safe and operational conditions?

- Should the training effort start more upstream in the education system or in dedicated training organisations to develop competences?

- Is there a return on investment from training?

To answer these questions and help customers resolve their “make or buy” decision-making process,let’s look at four main domains:

- Initial and basic training

- Aircraft type and related training

- Continuation training

- Structure training

For many years Airbus primarily focused on type training. Today, Airbus offers a full range of training to accompany maintenance personnel in their career path from beginner level to expert.

1. Initial and basic training

There is a massive demand for aircraft maintenance technicians and engineers over the next 15 to 20 years. Meanwhile, the main challenge for operators and maintenance repair organisations is to hire personnel with suitable competences to ensure safe and efficient maintenance operations, but also to reduce training efforts and associated costs. For today’s aircraft maintenance technicians, the journey starts much earlier in each country’s education system where future talents are captured and oriented toward aircraft maintenance basic training and/or more general aeronautical engineering studies. However, some organisations hiring young and new maintenance personnel from schools find there is still a lack of knowledge and competences. On top of the on-the-job period, organisations then have to implement intensive training programmes to bring this new population of mechanics to the expected level. In many cases,maintenance organisations develop their own Maintenance Basic Training school. To help airlines and organisations, Airbus has engaged in a programme to support academies in bringing the training effort upstream in the education path, providing them with:

- suitable industry standards

- access to modern aircraft technology data and material

- new teaching solutions more attractive to the new generation

The aim is to prepare young aerospace students for a career in the aviation industry, equipping them with the necessary skills acquiring basic knowledge of modern aircraft to meet their career challenges,and to minimise additional costly and time-consuming training efforts by customers, operators and maintenance organisations after recruitment.

Helping schools reach higher standards

Airbus offers support to bring basic training schools to the required level, EASA part 147, National Authority or equivalent. The service includes an evaluation of the school and the definition of the targeted standard and catch-up plan to fill the gap. It can also include the setting up of the school’s Maintenance Training Organisation and its associated documentation reference (MTOE); recommendations for the facilities (classrooms, labs, hardware…); training of the management, quality and instructor teams; the setting up of an FAQ question database; the associated examination tool and support for the school approval dossier to the relevant airworthiness authorities.

Bringing latest generation aircraft technology into the classroom – ACT for Academy

Supporting academies to implement programmes more attractive to the younger generation, with up-to-date technology and interactive teaching techniques, Airbus introduced ACT* for Academy, a lighter and customised version of the ACT suite solution used for type training, with the same concepts: “bring the aircraft into the classroom” and “learning by doing”. Airbus Competence Training (ACT) for Academy brings Airbus aircraft to schools using innovative virtual and interactive tools. It not only trains future generations of maintenance personnel to the latest aircraft technology and maintenance procedures but scales up their knowledge, skills and attitude on modern aircraft from the early stages to meet aviation industry standards.

*ACT Airbus Competence Training

2. Aircraft type and related training

Type training – required for each aircraft type – provides an already qualified mechanic with the knowledge, skills and attitude to perform maintenance tasks and issue certificates of release-to-service. Further to type training performed in a training organisation, the mechanic obtains a Certificate of Recognition which allows him/her to get the relevant aircraft type endorsed on his/her licence by the competent authority.

More on aircraft type training

Customer feedback about return on investment

Beyond the overarching safety aspect, the quality of training and subsequent competence acquisition have an obvious impact on maintenance efficiency, costs and aircraft availability performance. This is constantly being measured via trainee appraisals of the Airbus instructors and training material.

To better evaluate the return on investment on the training, Airbus launched two surveys: one on the A350 T1+T2 course and one on the A319/A320/A321 Engine Difference course. Over 150 trainees from more than 30 organisations contributed before and just after the course, then a few weeks or months later, once they were back in the field.

The results highlighted a real return on investment: 80% productivity gain. A few months after their training at Airbus the mechanics reported a two-fold increase in productivity compared to after other similar courses. The return on investment, all costs included (training, travel and living expenses, loss of productivity) is obtained within just a few weeks after training completion. This is based on quantitative savings from avoided delays or cancellations. The mechanics reported a big increase in their confidence level when performing maintenance operations on aircraft.

Customers reported that the training brings real value to operations, from both a qualitative and a quantitative point of view:

- “Airbus training has been a key part of the training for our new employees and senior staff to solve problems on the line.”

- “Airbus Training has a very strong competitive advantage and, thanks to the cooperation of the training sales staff and experts in training, we have managed to considerably improve our staff competencies.”

- “Training services provided by Airbus can flexibly meet our needs and bring efficiency to our daily work, through which our personnel can master the skills for their daily jobs.”

Thanks to a worldwide network of training sites and approvals from various national authorities, customers have a wide range of solutions with this “on demand” offer, which can assist them when defining their “make or buy” training strategy. Even if an organisation prefers to keep its type training in-house, it can consider using the Airbus ACT suite solution when deciding to “make or buy” training material.

Know more about the Airbus ACT Suite solution

3. Continuation training

Airlines and maintenance organisations are under pressure to improve operations, training, reduce turnaround time and ensure quality services to customers. Maintaining and developing competences of maintenance staff is required by regulations and is necessary to secure safe and efficient maintenance operations.

Different options are available:

- Refresher training to stay proficient;

- Training on new design changes, new configurations within the same aircraft type;

- Training on in-service events to learn from experience;

- Specific training: Fuel Tank Safety (FTS), Electrical Wiring Interconnection Systems (EWIS) and Human Factors (HF).

More about continuation training

4. Structure training

Because an aircraft structure is exposed to different types of damage (accidental, corrosive/environmental, fatigue/ageing), maintenance organisations require specific competences to perform damage assessment and/or damage repair using the manufacturer documentation and/or specific repair solutions.

To help develop these competences for traditional metallic structures and for new composite ones, Airbus Training proposes a state-of-the-art structure training solution. It can be generic to structure principles or very specific to a given aircraft design. In particular, because of emerging new generation aircraft, the structure learning path is by profession and aircraft type.

As for maintenance with the ACT suite solution, Airbus is working on a proposal for customers to perform “in house” training with its training material.

Airlines, MROs and lessors need not only typical type training for mechanics; they also need to take on a new generation of aircraft maintenance technicians and engineers at a high speed. Their primary purpose is not to train personnel but rather to ensure the right competences at the right time in order to guarantee aircraft safety and optimised maintenance operations.

End-to-end comprehensive training provides support to universities and maintenance basic training schools as well as maintenance organisations. Quality training is key in helping mechanics develop and maintain both competences and confidence. The result can be seen in the efficiency of maintenance operations. The Airbus Modular and Integrated End to End Maintenance and Structure Training solution aims at meeting customers’ needs and expectations, but also helping to solve any dilemmas about “make or buy” training and showing that training is indeed a value-adding investment, not just a cost to bear.

Source – Airbus.com