✔First thing Airframers like ‘Airbus’ & ‘Boeing’ do to their ‘aircraft design plan’ is to involve a ‘Propulsion system maker’ like GE, Rolls-Royace, P&W or others.

✔Sometimes this chemistry between Airframer & Engine maker does not work.

✔Last week, we witnessed Rolls-Royace freezing it’s ambitious ‘UltraFan’ Project despite deep financial back up, much hype & cutting edge technology involved to it.

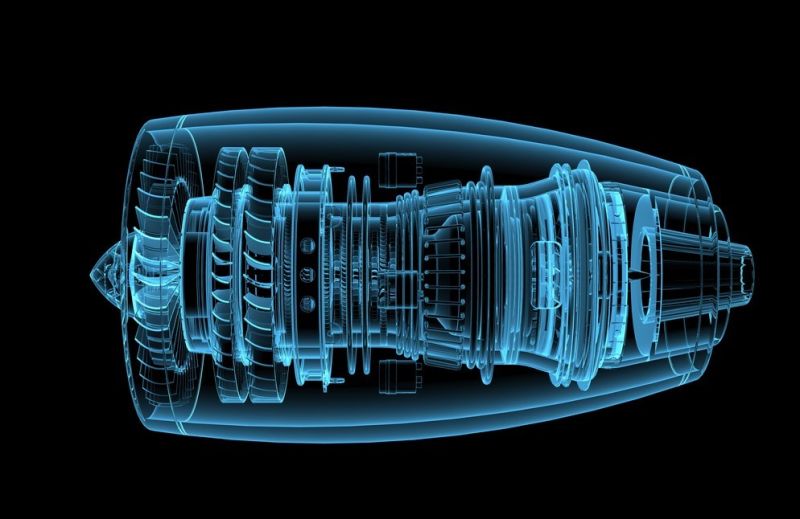

✔The Factors that really affect a commercial aircraft engine concept design are:

✔Business Case Of Engine.

👉Developement Cost.

👉Manufacturing cost.

✔Revenue source for Engine.

👉Engine Unit sale.

👉Sales Volume/Market demand.

👉Spare parts/Supply chain.

✔Aircraft specific Requirement.

👉Passengers capacity.

👉Cruise speed & Insertion altitude.

👉Balanced field length.

👉Power & bleed air-off takes (usage).

✔Customer Interest value.

👉Revenue Generation.

👉Payload Offer.

👉Range definition.

✔Cost of Ownership.

👉Price of engine.

👉Fuel Burn (efficiency).

👉Maintenance cost.

✔Regulatory Requirement.

👉Safety.

👉Noise.

👉Emissions.

Author – Tanmay Palei

Sr. Aircraft Structure Engineer