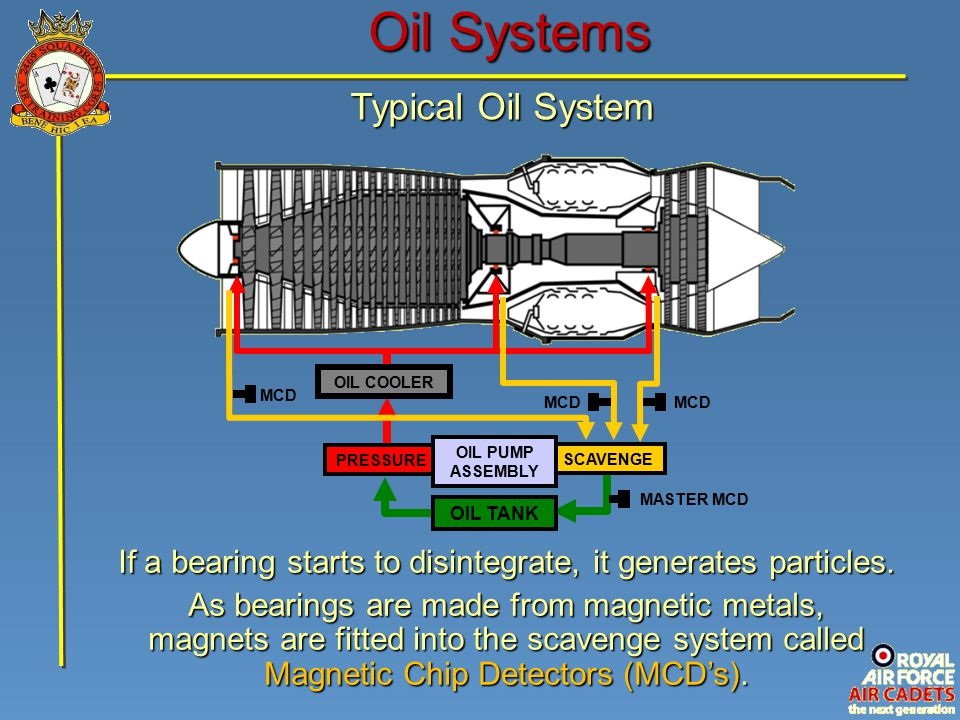

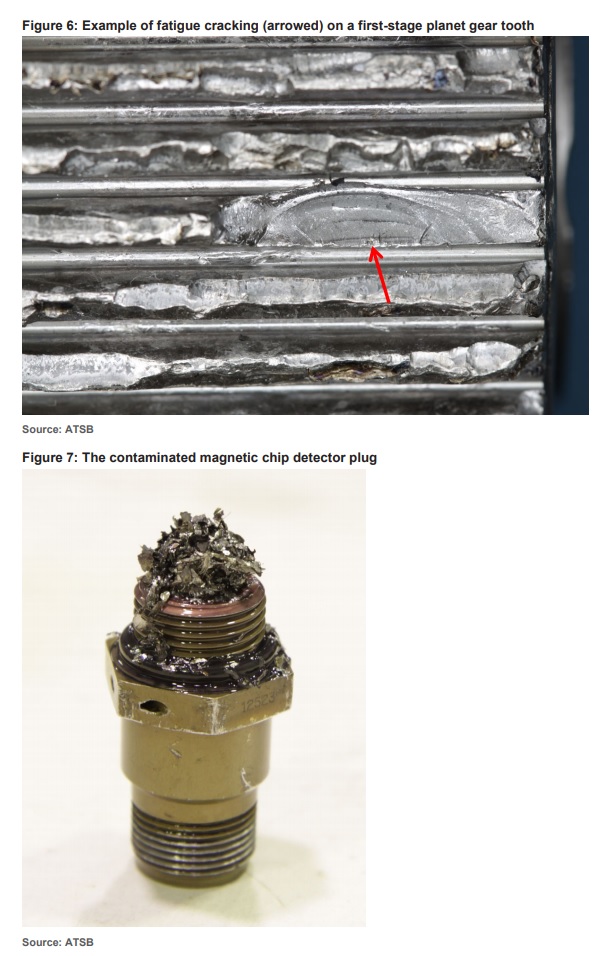

Metal particles in the lubrication system of an aircraft engine or hydraulic system may be an indication of wear. Chip detectors are used to monitor these systems to provide early warning of impending failure so that maintenance can be performed on a timely basis. The detector houses magnets incorporated into an electric circuit.

Magnetic lines of force attract ferrous particles. Collection of these particles continues until the insulated air gap between the magnets (two magnet configuration) or between the magnet and housing (one magnet configuration) is bridged, effectively closing the circuit.

The result is an electronic signal for remote indication. Chip detectors may be positioned in the application with a self-closing valve/adapter through either a bayonet or threaded interface. As the chip detector is disengaged from the valve, the valve closes minimizing any fluid loss from the system.

On Jun 15th 2019 Pakistan’s AIB released their final report concluding the probable cause of the serious incident was:

The occurrence was caused due to failure of No 30 Bearing of the engine however the exact cause of No 30 Bearing failure couldn’t be established due to excessive damage.

The AIB reported the first officer noticed a flight asymmetry in the flight conditions while on final ILS approach to Karachi, the captain took control of the aircraft. A Master Caution along with an EEC and subsequent PEC light for the left hand engine occurred. The crew shut the left hand engine down and continued for a safe landing.