Blade machining moves to a new level

Competitive manufacturing blades for steam and gas turbines is challenging with machining containing most of the demanding factors in metal cutting:

- part materials have varying machinability (some of them poor, needing dedicated inserts),

- considerable amounts of material have to be removed and good surface finish has to be achieved (without affecting the blade negatively, for example in terms of residual stress),

- component form is complex (some needing advanced CAM-programmes with the best methods),

- blades are prone to vibration during machining (long, slender, thin parts that need light-cutting tools and dampening abilities),

- production efficiency is important (large volumes are made),

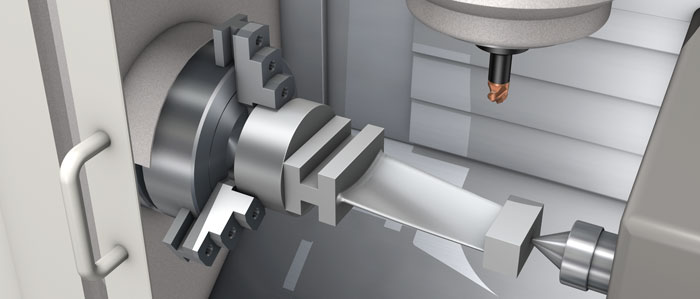

- several different tools have to be used and applied correctly (straightforward face milling to 4- to 5-axis profiling).

Well-worked out machining strategy with continuous improvements is crucial to productivity and subsequent processes. Innovative tooling and qualified application is the only way to meet the challenges involved especially the rotating blades.

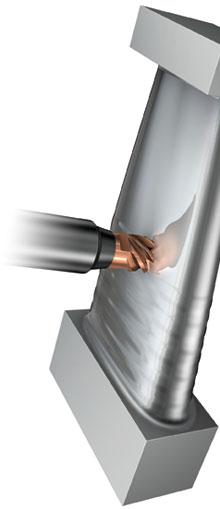

Roughing the blade rhombus and aerofoil, of especially medium-sized blades, from blanks, to achieve the basic blade form is often at the centre of attention as it represents the bulk of machining. Many of these are made in martensitic stainless steel but blades are also made in Duplex, HRSA and Titanium. This operation has seen a number of different solutions through the years but round-insert milling cutters and ball-nose end mills have become the main direction through their ability to generate profiles with a secure and strong cutting edge and also their cutter-to-part clearance.

When one milling cutter is used for the rhombus-roughing, a large amount of cutter engagement with the part is an important success factor, with 60 to 80% being the target. This has to be achieved by applying the most suitable cutter diameter in combination with the most advantageous tool path. Also the best balance between feed, depth of cut, size of insert, geometry and grade of insert, pitch of inserts as well as the cutting forces generated should be established to achieve optimized performance, security and results.

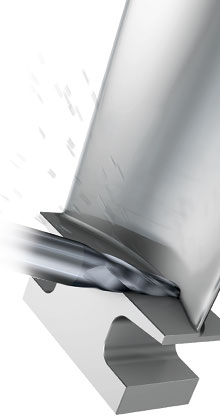

Roughing the roots of the blade, especially the transition between head and foot, (hub and shroud) is an important follow-up operation to get right as this also represents considerable amounts of material but is not suitable for the round-insert cutter of the rhombus because of the corner and shoulder involved. This needs a special solution to achieve high efficiency.

Semi-finishing and finishing of the blade also requires the best tool and method solutions to achieve quality at high efficiency. A complimentary round-insert milling cutter, solid carbide end mills and a modern, suitable face mill applied with advanced methods, to suit the blade size and form as well as the machine and programme possibilities involved, will complete the set-up.